Delivery condition: Hot forged, Heat-treatment (Normalized / Annealed /Quenched / tempered), Rough machining.

Test: Ultrasonic and magnetic test according to customer' require(EN orASME)

.Size Tolerance:

Length tolerance: +100mm/-0mm

Side length tolerance: +/-2mm

Straightness: max 6mm/m

7. Quality requirement

Both end of each bar must be cut.

Ladle furnanced and vacuum de-gassed

Show heat No. on each bar

Surface condition the surface of the hot rolled square bar shall befree cracks, scar and wrinkles that affect the use of the billets. In case there is the above-mentioned defect, it shall be remove.

The mill test certificate shall show the chemical composition, and it is guaranteed that the chemical composition shall be within the limit stipulated in the contract.

forged round bar of SAE4140

1. Forged steel round bar

2. Material:SAE 4140,SCM440,42CRMO4

3. Length:3.5m plus

4. Both ends: plain square end with end hole remained and debarred.

5. Diameter tolerance:-0/+2mm

6. Straightness: Max 2mm/M

7. Out of roundness: Max 2mm

8. Delivery condition: Hot forged +Rough machined/T (black surface after Q/T)

9. UT test: As per Sep 1921-84 Class 3 C/c (FBH 6mm,6dB acceptable)

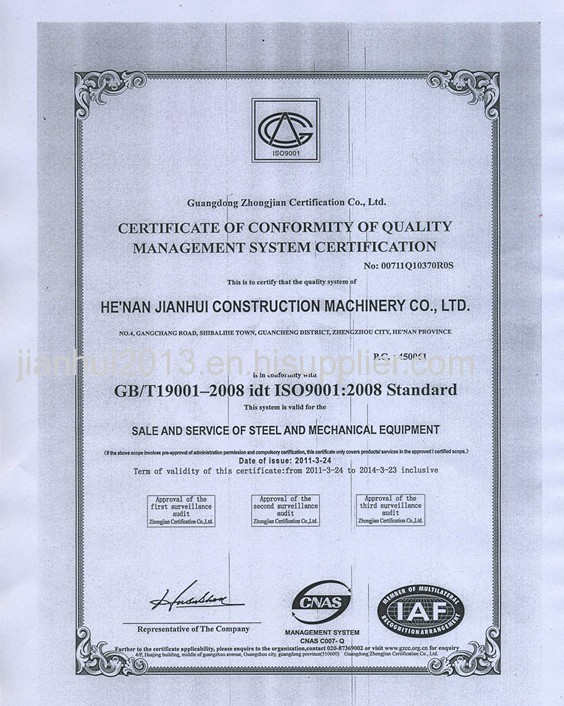

ceritificate

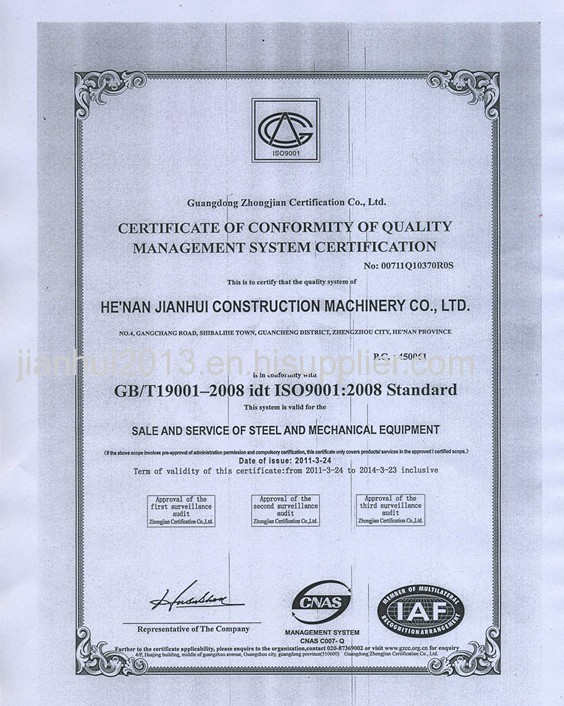

ceritificate