|

Henan Jianhui Construction Machinery CO.,LTD

|

| Price: | 1200.0~2000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

We can supply various sizes of Grade Q235B Steel H-beams on the basic of different Standards, Our company has been exporting our high quality products with very competitive prices to Middle East, Southeast Asia, South America for many years, and have won a lot of our customers' trust and support. And now our sales market is extending to the whole world. any necessary ,connect with us ,

E-mail: jianhuisales@hotmail.com

Tel: 86-371-86059106

Name US420 J2 Stainless steel coil /sheet

1.Type Hot-rolled, Cold-rolled.

2.Thinckness :0.3mm-80mm.

3.Widthness :1000mm-2000mm.

4.Length :as customer's requirement.

5.Surface Finish:2B/BA/8K/NO.1/HL/180G/320G/400G/600G/8K.

6.Standard:ASTM, EN ,BS,GB,DIN, JIS etc.

7.Material:201,202, 304,304L,304J1,316L,321,309S,310S,410,420,430.

US420 J2 Stainless steel coil /sheet Application range Food stuff, Gas, metallurgy, biology, electron, chemical, petroleum,boiler, nuclear energy, Medical equipment, fertilizer etc

The raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, sheets and slabs.

The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath), electrocleaning (application of an electric current, using phosphoric acid and a cathode), etc.

Descalingof the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling, forging and extruding, the sheet and strip forms go through annealing after hot rolling.

Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

Surface finish, the final step in the manufacture of stainless steel, is critical to obtain the smooth and reflective surface that the metal is popular for. This last stage gives the product the desired corrosion resistance and gets the metal ready for further specific industrial manufacturing steps as required. In the surface finish stage, the metal is subjected to treatment according to the physical appearance desired: a dull finish, a bright finish or a mirror finish.

Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

The raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, sheets and slabs.

The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath), electrocleaning (application of an electric current, using phosphoric acid and a cathode), etc.

Descalingof the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling, forging and extruding, the sheet and strip forms go through annealing after hot rolling.

Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

Surface finish, the final step in the manufacture of stainless steel, is critical to obtain the smooth and reflective surface that the metal is popular for. This last stage gives the product the desired corrosion resistance and gets the metal ready for further specific industrial manufacturing steps as required. In the surface finish stage, the metal is subjected to treatment according to the physical appearance desired: a dull finish, a bright finish or a mirror finish.

Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

ceritificate

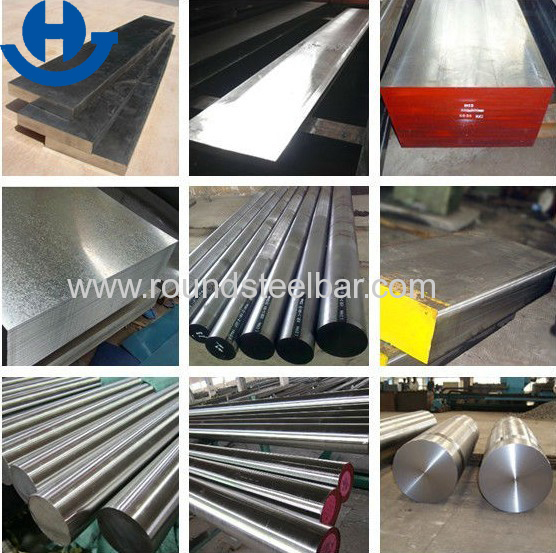

Production Equipment

Processing Equipment

Black Steels

Peeling Steels

finished steel

Testing Equipment