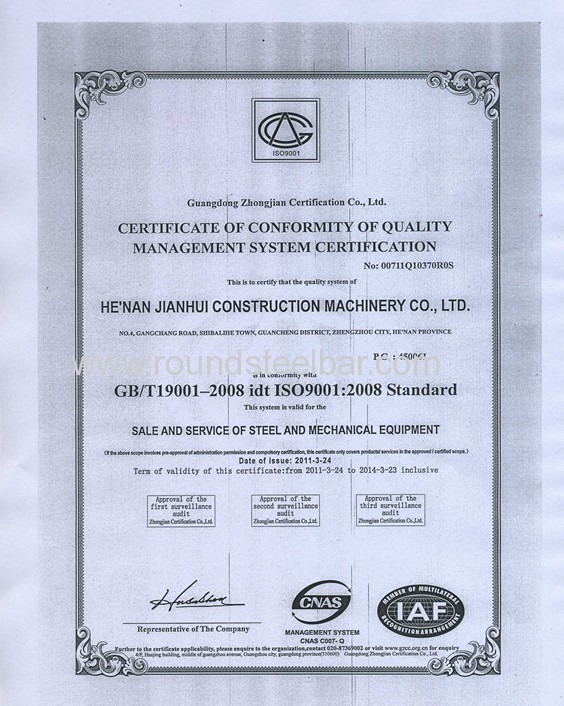

My company Henan Jianhui Construction Machinery Co. Ltd has been audited as

by Made-in-China website and global source website. Besides that, at the company we adhere to and contribute to the efficiency of our quality system in every aspect of our business. Our commitment guarantees to provide our clients with uncompromising quality and service. This is achieved through a team approach where all the members are aware of the company objectives and work within their own discipline to make an effective contribution.

I

Specification of Tool Die Steel L6

Tool Die Steel L6 Round bar; diameter 50mm—450mm

Tool Die Steel L6 Flat bar: thickness: 20-200mm, width: 300mm—5000mm

4. Principal Design Features of Tool Die Steel L6 This is one of the Special Purpose, low alloy tool steel grades, similar to the W group of low alloy tool steels. L6 contains nickel, chromium and molybdenum for a good combination of toughness and harden ability.

5. Applications of Tool Die Steel L6 Typically used in machine tool applications such as bearings, springs, rollers or chuck parts.

6. Machinability of Tool Die Steel L6 : Machinability ofTool Die Steel L6is very good. It rates 90% of the mach inability of the W group water hardening low alloy steels rated 100% as a baseline.

7. Forming of Tool Die Steel L6:Tool Die Steel L6 may be readily formed by conventional means.

8. Welding of Tool Die Steel L6:This alloy is wieldable. Consult the supplier for proper procedures.

9. Heat Treatment of Tool Die Steel L6: Heat slowly to 1500 F and hold at temperature for 10 to 30 minutes. Oil or water quench.

10. Forging of Tool Die Steel L6: Forge at 1975 F down to 1600 F. Do not forge below 1550 F.

11. Hot Working of Tool Die Steel L6:See "Forging".

12. Cold Working of Tool Die Steel L6: L6 may be cold worked by conventional means as with the low alloy steels.

13. Annealing of Tool Die Steel L6:Anneal at 1450 F and slow cool at a maximum of 40 F per hour.

14. Agingof Tool Die Steel L6: Not applicable to this alloy.

15. Tempering Tempering is done in the range of 350 F to 1000 F for Rockwell C 62 to 45 ranges.

16. Hardening of Tool Die Steel L6:See "Heat Treatment" and "Tempering"

17. Payment for Tool Die Steel L6:We accept 30 percent advance by T/T, the balance 70 percent by T/T or L/Cwould like you to know we can provide the high quality products and competitive price.