1.

Chemical composition:

C 0.32-0.45, Mn 0.2-0.5, Si 0.80-1.2, P max0.03, S max 0.03, Cr 4.75-5.5, , Mo 1.1-1.75, V 0.8-1.2

2.Hot-rolled tool die steel H13 rolling bar DIa or distance is 8mm-80mm, Forging hot rolled tool die steel H13 bar dia or distance of 50mm-150mm

Hot rolled strip out thickness 3mm-30mm*width is( 10, 12, 14 and 16, 18, 25, 30, 40, 60, 90, 100, 160)mm

Forging flat steel thickness is 10mm-65mm, width is (40, 45, 60, 80, 150, 180, 200mm).

4. The Package of tool die steel H13 round steel bars:standard container package,or as custom requirement

5. Smelting characteristic of tool die steel H13 round steel bars:high hardenability,high toughness,good ductility,high temperature performance

6.Highlight advantage of tool die steel H13 round steel bars:high hot strength and hardness,good resistence to heat,good hot toughness,high resistance to temperature fatigue and wear in medium heat ,small heat deformation,the tendency of the appearing of iron oxide skin are small in air-quenching,excellent corrosion resistance

7.technological process of the tool die steel H13 round steel bars: EAF+LF+ESR+FORGED+ANNEL+UT+ PEELING / TURNING / MILLING

8.Delivery Status of tool die steel H13 round steel bars: Black surface/grinded/machined

9.Payment for tool die steel H13 round steel bars: advance 30% byT/T, balance L/C or T/T

10.Inspecting of tool die steel H13 round steel bars:TS according to SEP1921 C/c or GB/T6402

Characteristic application:

Hot die steel, the performance of high-toughness and heat resistance are good. It is suitable for the metal compression casting, the extrusion mould, duplicate mould, stamping mould and the plastic mould of PA, POM, PS, PE, and EP.

Hot-work steel with good high temperature strength and high wear resistance.

Die forging dies, die inserts.

Shrink rings.

Hot shear blades, trimming tools.

Hot bending tools.

Die casting dies.

Light metals processing.

Tools for extruding light alloys, eg. liners dies and mandrels.

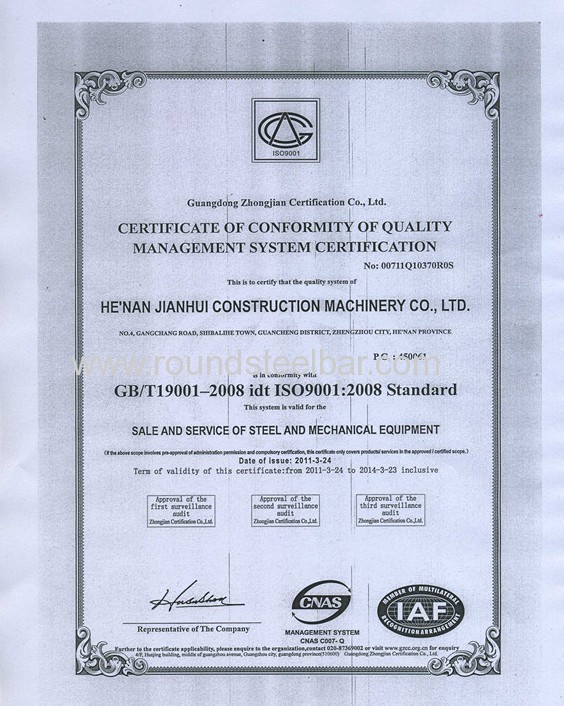

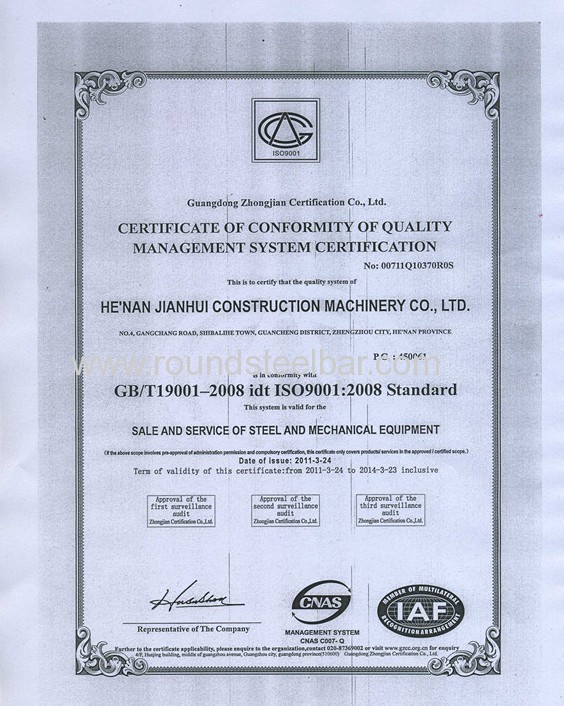

ceritificate